Managing risks when unpacking shipping containers

Safework Australia has recently updated its suite of risk management advice sheets regarding this topic.

The ones that I would like to talk about are:

& particularly

A few years ago I was involved in sales of PIDs (Photo Ionisation Detectors) which are excellent devices for measuring methyl bromide and some other fumigants. As a result of this I visited Customs and many other importers who regularly had containers to inspect or unload.

WARNING – QUICK RANT: At one point it was in the Customs procedure to use a PID to measure fumigants before & during inspection, then they dropped this from their procedure – WTF? I thought the government was supposed to set a good example!

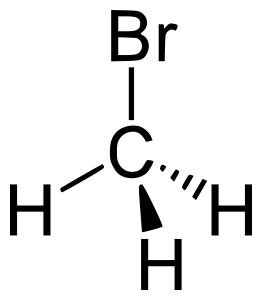

Many importers who receive either wooden products OR get their products delivered on wooden pallets (i.e. most of them!) have an issue with methyl bromide. Treatment of wood packaging requires a concentration of up to 16,000 ppm.

In tightly packed containers airing them or even using fans does not work as the gas gets trapped, only releasing when boxes are moved. In the case of machinery on pallets & held in place with plastic film, the gas tends to gets trapped inside the film, which needs to be opened to release it. Exposure in both these cases can easily exceed the safe working limit.

Can YOU say, hand on heart, that you are compliant with current exposure recommendations?

Methyl bromide is a sweet, almost pleasant smelling gas at levels above 5ppm (the exposure limit). It is GREAT at killing insects / pests. Unfortunately, it is also a neurotoxin for humans, affecting our Central Nervous System. It is also suspected of causing genetic defects. But perhaps the worst aspect is that it is a cumulative poison….

The 5 ppm concentration is the Australian occupational exposure guideline which is considered to cause no adverse health effects for exposures of eight hours per day, five days per week (that is, 40-hours weekly exposure). But what if you are getting short bursts of higher concentration?

It makes sense to equip employees with PIDs while performing this task or, at the very least, get someone in to take some REAL TIME readings as well as the more normal personal sampling.

It’s worth noting that in the USA the IDLH (Immediate Danger to Life & Health) limit is set at just 250 ppm.

Please feel free to comment below or ask questions about the various brands of PIDs available, I’m always ready to help and have no vested interests.

More reading:

http://hsis.safeworkaustralia.gov.au/HazardousSubstance/Details?hazardousSubstanceID=2458

https://en.wikipedia.org/wiki/Bromomethane

Good call. Kelvin. With advances in PID technology, most workplaces can’t claim that determining compliance with exposure standards is not practicable. For many common materials, it allows you to verify that levels cannot be greater than those recommended. They also let you visualise vapour flows to an incredible degree – I’ve tracked solvent vapours dropping like a stone and spreading along the ground, with almost nothing in the normal breathing zone.